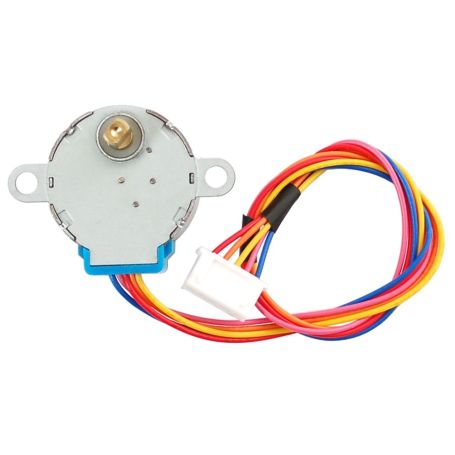

Stepper mortor - 12V, 32 step, 1/16 gearbox

Small uni-polar stepper motor 12V - 32 steps - reduction 1/16 - 512 steps per revolution

Payments are secured by LyraCollect, a French payment collection company.

It is possible to delivered to your home, to a pick-up point or picked up by appointment at MCHobby

We prepare, pack and ship your orders with great respect and care.

A 12V stepper motor with 512 steps per revolution

It's a super first stepper motor, excellent for small projects and stepper motor discoveries. This uni-polar motor has two emplacements/mounting holes integral with the motor. The motor doesn't have only 32 steps (11.25 degrees) per revolution but it incorporates a gear reducer having a 1/16.

This means that this motor really has 32*16 steps per revolution = 512 steps!

The axis is flattened, so it is easy to attach material with some screws/fastenings. It's a perfect stepper motor for a first experience and works well with the motor shield for Arduino.

The reduction gear, however, involves some side effect that is important to note. First, you can turn the axis of the stepper motor but it turns less freely than a stepper motor without reducer (the axis offers a slight resistance precisely because of the gears of the reducer). Then, it is better not to control this motor in interleave or micro-stepping otherwise it will take an eternity to make a revolution ;-) The use of a single or double stepping is ideal. The torque is quite high but the motor remains slower than a motor without reducer (maximum of about 80 RPM Rotations Per Minute).

Motor shield connection

You can use this motor with the motor shield for Arduino. Connect the red wire (middle) to GND (ground), the orange and the pink to a motor output (for example M1) and the blue and yellow wires to the other motor output (for example M2).

So in order we have: orange - pink - red - blue - yellow. Then use the sample code provided in the Adafruit Motor Shield Library and initialize the constructor as follows AF_Stepper motor(512, motornum) and set the speed to 5 rotations per minute by calling motor.setSpeed(5).

Other connection

You can also connect this motor with some transistors and use the Arduino stepper library.

Technical details

- Uni-polar stepper motor with a 5-pin connector with impaction of 2.54mm. Ideal for Arduino and Breadboard :-)

- 32 steps per revolution (excluding reducer)

- Gear reducer 1/16

- Suggested voltage: 5V-12V DC

- Weight: 37 gr.

- Dimensions: 28mm diameter, 20mm thick + 9mm axis having a diameter of 5mm.

- 23 cm long cable

- Torque to the axis under 12 Volts: 2.5 N*cm = 25 N*mm = 0.025 N*m ( 0.255 kg*cm )

- Axis: 5mm diameter flat

Dimensions and detail of connector + coil connection on our Wiki page.

To fix the ideas concerning the torque:

1 newton-meter is equal to 100 N-cm, or 10.1971621298 kg-cm (the force exerted by a weight of 10Kg at the end of an arm of 1 cm).

Tutorials

- See motor shield for Arduino

- Stepper motor control with a Raspberry-Pi and ULN2803A in French

- This Arduino page. CC dedicated to the Arduino stepper library.