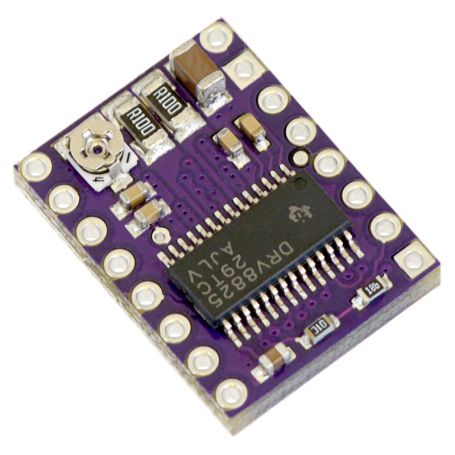

[T] - DRV8825 - Stepper motor controller

DRV8825 stepper motor controller - micro-step, high current

Payments are secured by LyraCollect, a French payment collection company.

It is possible to delivered to your home, to a pick-up point or picked up by appointment at MCHobby

We prepare, pack and ship your orders with great respect and care.

Description

This DRV8825 stepper motor control breakout is based on the Texas Instrument DRV8825 which can drive a stepper motor in micro-stepping (micro step). The module has a pinout and interface almost identical to our A4988 stepper motor controller. It can therefore be directly used as a replacement on the various interface boards with this high performance model.

The DRV8825 incorporates an active and adjustable current limiter. You also have protection against overcurrent, overheating with 6 micro-stepping resolutions (up to 1/32 of a step). It operates between 8.2 and 45 V and can deliver approximately 1.5 A per phase without cooling or forced air - designed for 2.2A per coil using an efficient/adequate cooling system.

We recommend that you read the DRV8825 datasheet (1Mb pdf) and our tutorial carefully before using the product. This driver is capable of controlling a bipolar stepper motor with a current of up to 2.2 Amp per coil (see the section dedicated to Heat Dissipation for more information).

Active current control - a key advantage

This stepper motor driver has an active current limiting circuit. This is a pretty incredible feature because it allows you to drive stepper motors with higher voltage without grilling the motor.

Suppose you have a motor designed for 2.8V at 1.7 amps. If it is supplied directly with a voltage of 5.6 Volts (twice as an example) then the coil would pass a current of 3.4 Amp.

However, at 3.4 Amp, the coil heats up so much that the motor quickly burns out (the heating increases with the square of the current!).

But if you have a circuit actively limiting the current, you could set it to 1.7A max (or 1.5A, the maximum of the DRV8825).

Therefore, even if you supply the motor with 5.6v, the current cannot exceed 1.7 Amp (1.5A for the DRV8825) and the motor doesn't burn out.

What are the advantages of using a higher voltage?

- The motor is much more reactive.

The passage from one step to another faster with a higher voltage because the magnetic field is more powerful. - If the motor is more reactive then you can also reach higher speeds.

- With a higher voltage, you can use a pilot requiring a higher minimum operating voltage (like the DRV8825) even with a motor at fairly low voltage. As long as the current is actively limited, there will be no damage to the coils.

Regarding the 2.8V 1.7Amp motor mentioned, you could control it with a 9V power supply (confirmed by Pololu) with a DRV8825 by actively limiting the current to 1.5Amp (the maximum tolerated by the DRV8825 without cooling).

Characteristics

Here are some of the key features:

- Super-simple control interface for steps and direction.

- 6 step resolutions: Full step, half step, 1/4 step, 1/8 step, 1/16 step and 1/32 step

- Adjustable current control allowing you to set the maximum current that can pass through the coils. The adjustment is made using a potentiometer. So you can use your stepper motor with higher voltage ... allowing you to reach higher speeds.

- Intelligent chopping control that automatically selects the correct current decay mode (fast or slow decay).

- Max supply voltage: 45 V

- Integrated voltage regulator (so no external voltage needed to supply the control logic).

- Can interface directly with 3.3 V and 5 V systems.

- Automatic shutdown in the event of overheating. Shutdown in case of overcurrent.

Blocking at under-voltage (to avoid erratic/unpredictable operation of the control electronics) - Short-to-ground and shorted-load protection.

- 4-layer board using more copper to improve heat dissipation.

- Solderable ground pellet exposed under the integrated circuit (on the lower surface of the board).

- The module size, pinout and interface corresponds to the StepStick A4988 in many aspects (see the tutorial for more information).

- DRV8825 Datasheet

Content

The DRV8825 stepper motor driver with a pinHeader section (16 pins, 2.54mm impaction). The pinHeader can be soldered onto the board if you want to use it with a breadboard. You can also directly solder the motor wires and control signals directly on the board.

Caution: If you weld the pinHeaders on the board with the silkscreen above, this has the advantage of making pin identification very easy but the disadvantage of making the current limiting potentiometer almost inaccessible. If you want to drive it with this orientation, we recommend that you make the current limit setting before welding the connectors.

Tutorial

- The tutorial in French on the DRV8825 with Arduino.

- See the DRV8825 datasheet at Pololu (Pololu, English)

![[T] - Moteur pas-à-pas - 12V, 200 pas - Pro Moteur pas-à-pas - 12V, 200 pas](https://shop.mchobby.be/393-home_default/moteur-pas-a-pas-12v-200-pas.jpg)

![[T] - DRV8834 - Controleur moteur pas-à-pas basse tension DRV8825 - Controleur moteur pas-à-pas](https://shop.mchobby.be/1153-home_default/drv8825-controleur-moteur-pas-a-pas.jpg)