Micro-motor 1000:1 LP - 3mm D shaft - metal gearbox

Micro-motor - 1000:1 gearbox - 3mm D shaft - Low Power, metal gearbox

Payments are secured by LyraCollect, a French payment collection company.

It is possible to delivered to your home, to a pick-up point or picked up by appointment at MCHobby

We prepare, pack and ship your orders with great respect and care.

The best micro-motor to propel a robotic plateform (1000:1 ratio)

This micro motor is usually called "micro metal gearmotor" on internent. This is a brushed motor designed to work at 6 volts DC.

In a general matter, you can use this motor with a lower or higher voltage. So, you can drive the motor with a voltage between 3v to 9v (the shaft start to rotate from 0.5v). Using a lower voltage is not always easy and using a higher voltage will reduce the lifetime of the the motor.

This is a "Low Power" version of the motor which is well suited for the project having a limited power supply.

The micro motor with metal gear box does exists with various gear ratio (so various speed and torque). You can have a gearbox with a ratio from 5:1 down to 1000:1 (1000 turns are needed on the motor shaft to have 1 turn on the gearbox output shaft).

A more important ratio means a lower speed on the gearbox output shaft but you also have a bigger torque ("turning force"). The torque is increasing in the opposite way of the speed (lowering in this case). Slower is the motor and higher torque he will have :-)

There is 3 kind of motor:

- HP: High Power - thoses High Power Motor have an important stall current rated at 1600mA @ 6v (the current is always at the maximum when the motor's shaft is blocked).

- MP: Medium Power - motor having a stall current of 700mA @ 6V.

- LP: Low Power - motor having a stall current of 360mA @ 6V.

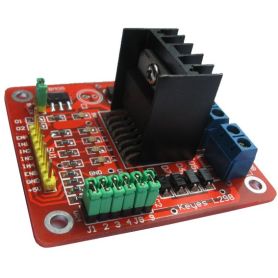

More powerful is the motor will provide higher torque on the gearbox output shaft. In counterpart, more powerful motor also need a more powerful driver (driving electronic). By example, a L293 can drive a LP motor (maybe a MP motor if you do not stale it). If you want to drive a HP motor then a L298 would be a better choice (see the "accessories" section).

All the gearbox micro-motor have the same size, so you can easily replace a motor by another one when needed. Please, note that some motors also have a shaft available behind the motor (Diam. 1mm, 4~mm length). This second shaft can be used to place a rotary encoder... quite useful to know the motor speed or count the shaft rotation.

Technical details

- Size: 24 x 10 x 12 mm

- Weight: 9.70 gr

- Shaft diameter: 3mm (D Shaft)

- Gearbox Ratio: 1000:1

- Speed no load (6v): 14 rpm (rotation per minute)

- Current - no load (6v): 40 mA

- Stall current (6v): 360 mA

- Stall torque (6v): 0.49 Nm (5Kg-cm)

Content

For each order, you will receive a motor. The wheel, motor bracket and other demonstration items are not included (we just use them to demonstrate the motor usage.

Tutorial

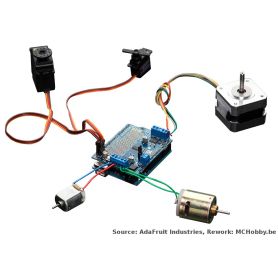

It is really easy to use those motors in you projects. You will need an appropriate electronic component to drive the motor. The selected component must support the adequate power. Here is some "french" tutorials... but it would be easy to find some english tutorial on the net

- Drive a DC motor with a L293D H-Bridge with Arduino.

- Drive a DC motor with a L298D H-Bridge with Arduino

- CDrive a DC Motor with a L298 and Raspberry-Pi

- Some other tutorials to drive DC Motor with Raspberry PI

- Use a DRV8833 - a DC motor controler.

![[T] - Micro Motor Support (Bracket) Support Micro-Moteur (Bracket)](https://shop.mchobby.be/1047-home_default/support-micro-moteur-bracket.jpg)

![[T] - Wheels 32x7 - White Roues 32x7 - Blanc](https://shop.mchobby.be/1052-home_default/roues-32x7-blanc.jpg)

![[T] - Roues 60x8 - Blanc Roues 32x7 - Blanc](https://shop.mchobby.be/1056-home_default/roues-32x7-blanc.jpg)

![[T] - Kit chenille - 85mm entre-axe Kit chenille - 85mm entre-axe](https://shop.mchobby.be/5171-home_default/kit-chenille-85mm-entre-axe.jpg)