Motor 12V 50:1 - 6mm D shaft - 37D - metal gearbox - 64 CPR encoder

12V motor - 50:1 with CPR encoder

- with CPR rotation encoder

64 count per revolution - motor ratio 50:1

- Shaft 6mm D

- metal gear box

- 37Dx70L

Payments are secured by LyraCollect, a French payment collection company.

It is possible to delivered to your home, to a pick-up point or picked up by appointment at MCHobby

We prepare, pack and ship your orders with great respect and care.

Fine controling the position of your robot motors with an motor fitted with CPR rotation encoder

This powerful motor with gearbox reduction is identical to our 50:1 12 volts motor but have a quadrature encoder used to know the position of the shaft or the number of turn made by the shaft.

This encoder have a counting resolution of 64 edges per revolution of the motor shaft, which make a total counting of 3200 per revolution behind the gearbox.

The motor shaft is 16mm long for a diameter of 6 mm (with a D-shaft).

The main features of the motir are:

- 12V

- 200 RPM and 300mA (without load)

- 120.04 N-cm (12 Kg-cm)

- A blocking current of 5A.

- Weight: 188gr

This motor is designed for 12V usage but can be used at a lower or higher voltage (it start to rotate at 1V).

Please note that using the moteur with a voltage greater than 12V will reduce its time of life.

blocking or overloading the motor can also reduce the time of life and may also cause immediate damage to the motor. Blocking current can overheat the motor coil (and thermal damage)... thermal damage can occur within a second.

You can easily screw the motor by using bracket for 37D motor, you can also use a 6mm shaft hub to ease the coupling the motor to the project.

Reduction ratio

Exact ratio = (25 x30 x 25 x 40) / (10 x 10 x 15 x 10) = 50:1

Using the encoder

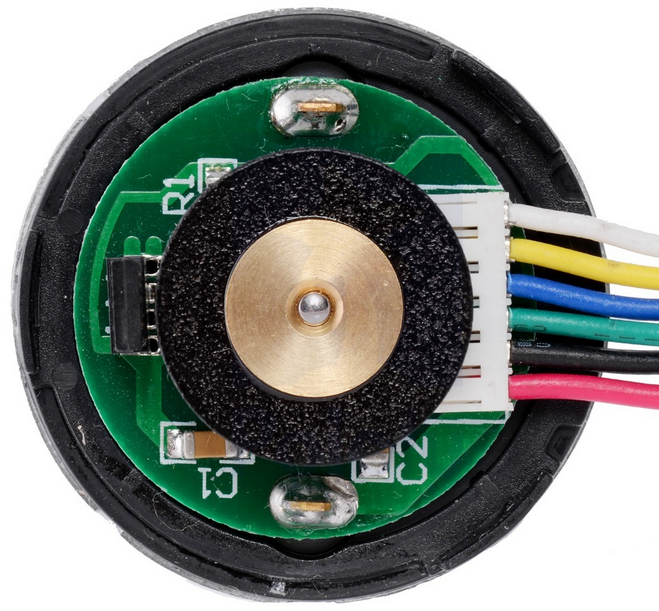

A two hall effect channel are used to detect rotation of magnetic wheel fit on the shaft (at the back of the motor). The quadrature encoder offer a counting resolution of 64 pulses per rotation of the motor shaft (when counting the edges on the both channels).

As the motor have a 50:1 gearbox, we do have 50x64 = 3200 pulses per shaft rotation (at motor output). Whoaw! we are able to have a really precise positionning of the motor.

The motor + encoder does have 6 wires availables (28cm, 2.54mm connector with 6 pins) as show by the image here upper.

The table, here below, show the function of each wire:

| Color | Function |

| Red | Motor power supply (directly connected to the first pin of the motor) |

| Black | Motor power supply (directly connected to the second pin of the motor) |

| Green | Masse/GND for encoder |

| Blue | Vcc for encoder (3.5V to 20V). ~10mA |

| yellow | Encoder - Ouput A |

| White | Encoder - Output B |

The Hall effect sensors a separate power supply (named Vcc, between 3.5 and 20 V). It draws about 10 mA.

The A & B output signals generates square waves with 90° out of step and output voltage between 0 to Vcc. The transition frequency gives an information about the motor speed where as the order of A - B transition would inform us about the direction (forward or backward).

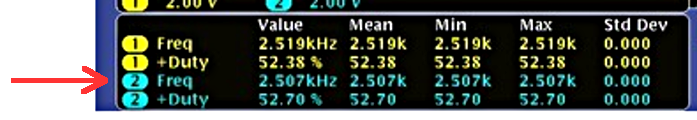

The oscilloscope capture here under shows the A signal (yellow) and B signal (blue) generated by the encoder. The motor is supplied with 12V and the encoder with 5V:

When counting the raising and droping edges on the both output A & B, we can seen 64 pulses by motor shaft rotation.

Counting only one edge (eg: raising edge) on only one channel reduce the counting value to 16 pulses per motor shaft rotation. As conséquence, the signal B frequency (blue curve) is precisely 2507 Hz as show by the oscilloscope (so 16 times the motor rotation frequency).

2507 Hz would gives us 2507 / 16 = 156.68 motor rotation per second, so 156.68 / 50 = 3.13 rotation per second behind the gearbox (remind, the gearbox ration is about 50:1).

Power consumption

It is difficult to classify this motor as LP (Low Power), MP (Medium Power) or HP (High Power).

The current inside the motor depend on the load applied on the shaft.

With no load, it draws 300mA (so LP classified). With high load, the current will be significant, the current can reach 5A while blocking the shaft (then we are over the HP classification).

The good way to classify the motor is to "measure the current while using it into your project". Current can be measured with amp.meter.

As advice, we would suggest to not use a motor at 100% of it load capacity (blocking current also named short-curcuit current) because this reduce the time of life of such appliance. Preferably stays under 75% of nominal capacity for best time-of-life.

Mounting with care

Be gentle when screwing the motor (on the front site). IF the screws are too long THEN they will go inside the gearbox and possibily damage the gear. Do not exceed 3mm long screws.

Content

This product containt only the motor with the CPR encoder. Wheel and holder are not included (used only to demonstrate the motor usage).

Tutorial

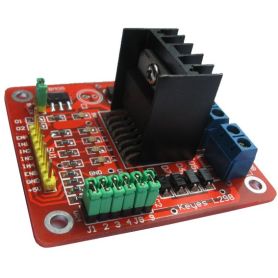

Using the motor is quite easy. Some electronics are needed to control the motor. Here is some tutorials (in french)...

- Drive a motor with L298 H-Bridge and Arduino (French)

- Drive a motor with L298 H-Bridge and Raspberry-Pi (French)

- Other tutorials about driving motors with Raspberry PI